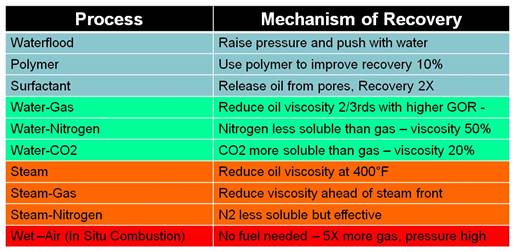

All improved recovery (IOR) or EOR methods start with injecting either water or gas, so the first IOR method that is always tested is a simple pattern or edge waterflood. The question here is “will injection of water recover oil more effectively than a natural water drive.” After that polymer can be added to raise the water’s viscosity and improve oil mobility. However, the effect of polymer is delayed, and the initial response of a polymer flood is just the waterflood response.

The other techniques listed in the table are EOR techniques since they make larger and more immediate changes to oil recovery. Any technique in which gas is coinjected with water or steam causes an immediate increase in oil recovery above that of a waterflood or steam flood because the gas reduces the oil’s viscosity ahead of the water. Carbon dioxide coinjection is the most effective of the water-gas techniques because CO2 is more soluble in the oil and reduces the oil’s viscosity more than reservoir gas or nitrogen.

As noted, steam just reduces the oil’s viscosity over 99% where the reservoir is hot enough. However, it takes time for a large fraction of the reservoir to be heated so, the initial response is similar to that of a waterflood. Adding any gas to steam has the same effect as it does in a waterflood. CO2 or any other gas reduces an oil’s viscosity most when the oil is cool and only reduces the oil’s viscosity a modest amount when the oil is hot. All gases have a second effect: They reduce the partial pressure of steam, so that steam condenses at a lower temperature, i.e., deeper in the reservoir. Thus, any gas makes steam more effective because it mitigates the unnecessarily high temperatures that can occur in a steam flood.

Wet-air injection combines reservoir heating, oil viscosity reduction, in-situ steam generation and a high-rate gas drive in one process where purchased fuel is not used to generate steam but steam is generated in situ by burning residual oil. Where it works, it is the most profitable thermal EOR technique. In this study wet-air injection means coinjection of 25 mole percent air with water that is preheated to 170°F. Preheating the water assures that oxygen will always be consumed, since oils autoignite quickly at temperatures above 170°F. This assures that there will always be a steam zone ahead of the combustion zone and that cool air cannot reach and bypass the combustion front to produce a corrosive or combustible mixture at the producers.